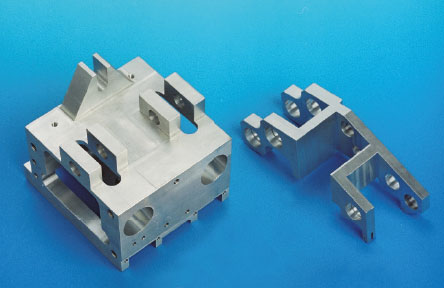

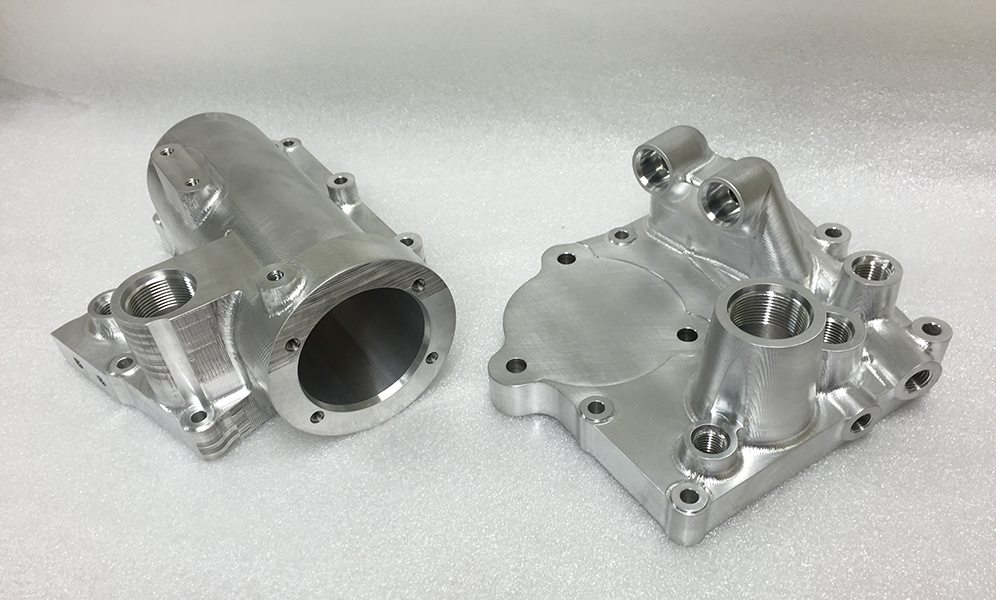

Frepa has the know-how to work with a huge variety of "exotic" materials such as titanium, Inconel, Monel, tungsten, ...

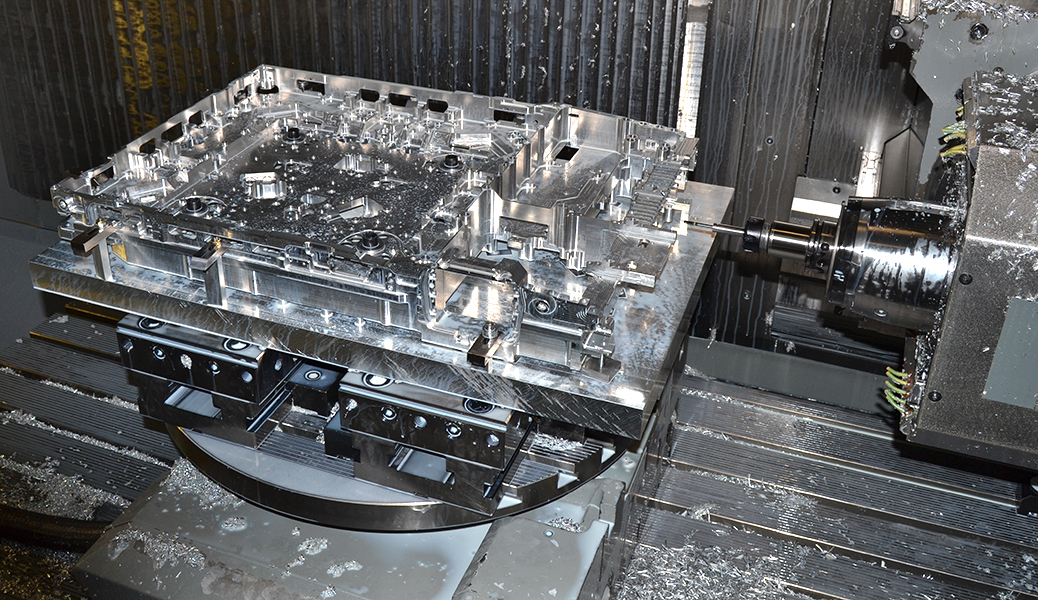

Frepa’s milling department contains the most advanced conventional and 5-axis CNC milling machines that can be found on the market currently. Some machines have a pallet change system.

The versatility of these machines makes it possible to tackle any milling job (workpieces up to 2,600 mm in length). The use of this ideal machine provides the client with at an excellent price-performance ratio.

Hard milling is also available.

OVERVIEW OF OUR CNC MILLING MACHINES

| DMF-260 | 5 axes | 2600 x 720 x 700 | 18.000 rpm | |

| DMF-250 | 5 axes | 2500 x 920 x 900 | 18.000 rpm | |

| DMU-95 | 5 axes | 1000 x 850 x 650 | 15.000 rpm | |

| DMU-85 | 5 axes | 1200 x 850 x 650 | 18.000 rpm | |

| DMU-80 | 5 axes | 1000 x 600 x 500 | 18.000 rpm | |

| DMU-75 | 5 axes | 750 x 650 x 560 | 18.000 rpm | |

| DMU-60 | 5 axes | 730 x 560 x 500 | 18.000 rpm | |

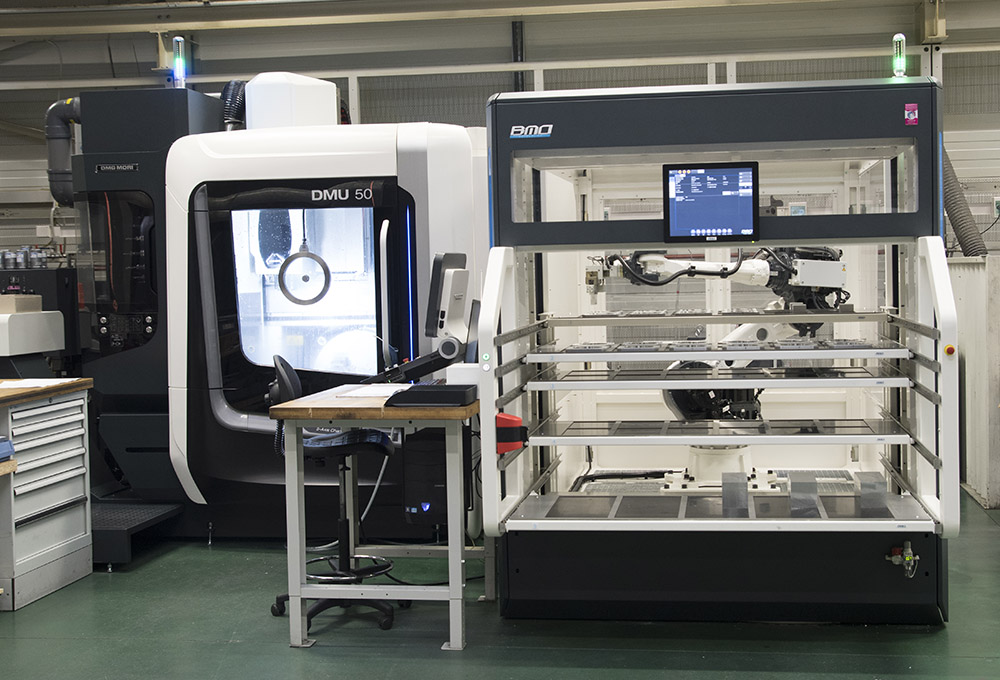

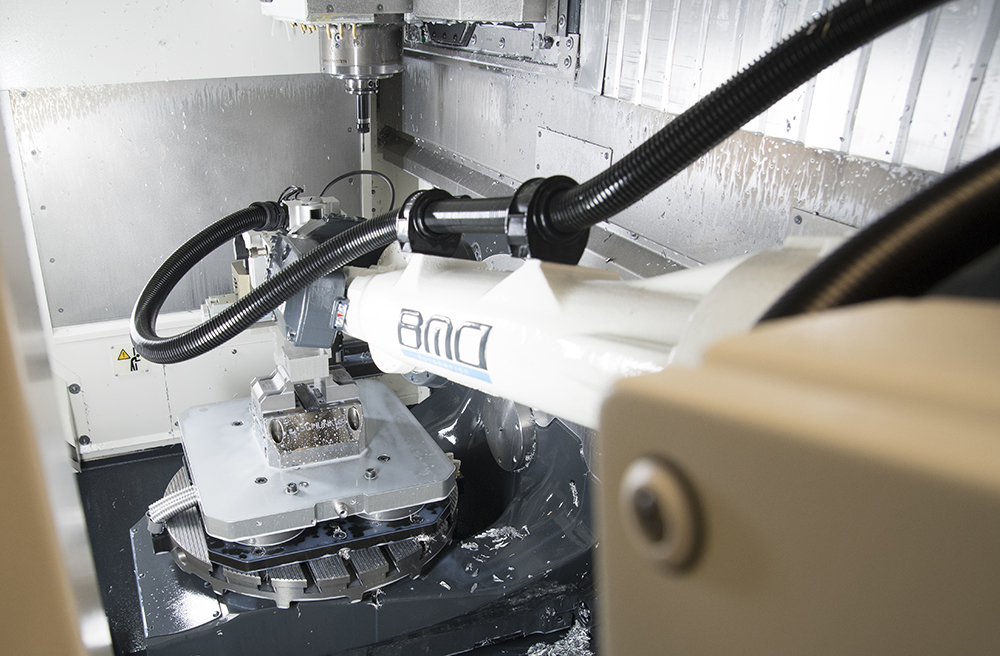

| DMU-50 | 5 axes | 500 x 500 x 300 | 18.000 rpm | with BMO robot cell |

| DMC-1450V | 1450 x 700 x 550 | 10.000 rpm | ||

| Matsuura 800 | 800 x 560 x 400 | 15.000 rpm | (high speed with pallet system) | |

| Matsuura 1000VF | 1000 x 600 x 400 | 15.000 rpm | (high speed) | |

| Matsuura 1000 RA-4f | 1000 x 500 x 400 | 15.000 rpm | (high speed with pallet system) |

|

CNC MILLING MACHINE DMU-50 WITH BMO ROBOT CELL

To automate both large and smaller productions, Frepa invested in a DMG Mori DMU-50 milling machine linked to a BMO robot cell.